Liquid Soap Filling and capping machines

Our Filling Machines are designed to fill the empty bottles with liquid soap and liquid detergent. After the filling stage, our Cupping Machine close the bottle putting the cap and fixing it.

LIQUID SOAP FILLING MACHINE FM-1000

• body in stainless steel AISI 304

• filling group composed of:

• anti-accident protection on the filling unit made with aluminum profiles, transparent PVC walls, safety microswitch to block the machine when the doors are opened.

• supply voltage: single phase 220 volts.

• possibility of operation by pedal control.

• manufactured according to CE standards.

• filling group composed of:

- 1000 ml dosing piston. to carry out dosages from 100 to 1000 ml. in AISI 316 stainless steel with relative valve.

- 100 ml dosing piston. to carry out dosages from 15 to 100 ml. in AISI 316 stainless steel with relative valves.

- 2 dispensing needles in AISI 316 stainless steel, to be mounted on a height-adjustable support.

- 2 sets of suction and product outlet pipes

- crank mechanism for adjusting the dosage

• anti-accident protection on the filling unit made with aluminum profiles, transparent PVC walls, safety microswitch to block the machine when the doors are opened.

• supply voltage: single phase 220 volts.

• possibility of operation by pedal control.

• manufactured according to CE standards.

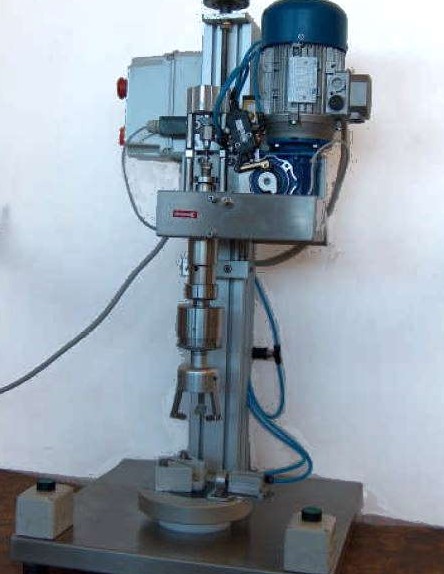

CAPPING MACHINE CM-1000

The machine is supplied with:

- support frame in AISI 304 stainless steel for bottle support

- aluminum support column, for screwing head

- TIGHTENING HEAD with magnetic hysteresis clutch equipped with head holder unit

- pneumatic control unit for closing the arms (without support on the cap)

- 3-arm spindle for screwing on a pump or cap size

- the head is lowered by pressing two separate buttons located on the machine plane

the machine also requires compressed air

Manufactured according to CE standards