Soap Extruder - Small Soap Machines

The Soap Extruders (also called Soap Plodders) are studied to refine, homogenize and extrude the processed soap (soap noodles + perfume + color) coming from the Mixer.

The Extrusion Cone ensures the extrusion of a compacted soap bar. The heating system of the extrusion cone is the same of an industrials soap extruder, to produce a bar with a smooth surface. Thanks to the Cooling Circuit, the soap extruders SE can work continuously without decrease the Capacity like happens in the soap extruder without circulating cooling system. The extrusion screws have a diameter of 80 or 120 mm; this last size is not only studied to increase the production (if compared with standard small extruders) but it is also able to produce a very compacted soap bar up to 150g of weight.

Our soap extruders are complete with Automatic Refining Group: a drilled plate with blades to homogenize very well the soap with the additives used in soap manufacturing.

We supply two models of soap extruders:

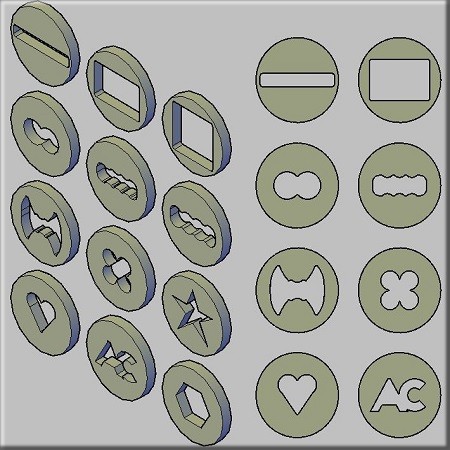

- Soap Extruder SE-80 SIMPLEX and SE-120 SIMPLEX that include a Drilled Plate to re-work and homogenize the soap and a shaping plate as per Customer specifications.

- Soap Extruder SE-120 DUPLEX, that is composed by two SIMPLEX connected with an hopper or a Vacuum Chamber. The first stage assembles a Drilled Plate to refine and homogenize the soap, while the second stage assemble an Extrusion Cone to extrude the soap bar by means of a shaping plate as per Customer specifications.

- Soap Extruders "SP" with higher performances and able to extrude special products

SOAP EXTRUDER "SE SIMPLEX"

- Capacity:- up to 50 Kg/h for SE-80

- up to 100 Kg/h for SE-120- up to 150 Kg/h for SE-120-SP - Manufacture in stainless steel

- Heated extrusion cone

- Cooling System with in/out

- Variable screw speed

- Including a shaping plate

- Maximum output:

- up to Ø 55 mm for SE-80

- up to Ø 75 mm for SE-120 - Installed power:

- 1,5 kW for SE-80

- 2,2 kW for SE-120- 3 kW for SE-120-SP - Electrical supply: 230 or 400 Volts

SOAP EXTRUDERS "SE-120 DUPLEX"

- Capacity:

up to 100 Kg/h for SE-120

up to 150 Kg/h for SE-120-SP - Manufacture in stainless steel

- Refining stage with drilled plate

- Connecting Chamber

- Extrusion Stage with cone

- Heated extrusion cone

- Cooling System with in/out

- Variable screw speed

- Including a shaping plate

- Maximum output: Ø 75 mm

- Installed power:

4,4 kW (6 HP) for SE-120

6 kW ( 8 HP) for SE-120-SP - Electrical supply: 230 or 400 Volts

VIDEO

SOAP EXTRUDER "SE-120-SP-VC DUPLEX"

- Capacity: up to 150 Kg/h

- Manufacture in stainless steel

- Refining stage with drilled plate

- Vacuum Chamber

- Vacuum Pump

- Extrusion Stage with cone

- Heated extrusion cone

- Cooling System with in/out

- Variable screw speed

- Including a shaping plate

- Maximum output: Ø 75 mm

- Installed power: 6 kW

- Electrical supply: 230 or 400 Volts